Parts Clearing & Coating

PARTS CLEANING & COATING

-

01

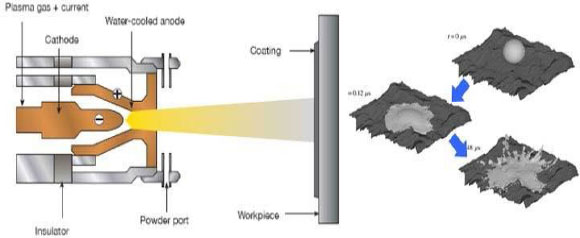

Coating Mechanism

Spray Coating Mechanism

Adhesion Mechanism

- Liquid coating material in flight

- Impact on surface

- Transfer of heat to the base material

- Solidification and contraction of the coating material

- Mechanical bonding

- Local diffusion or fusion (during heat treatment)

-

02

Coating

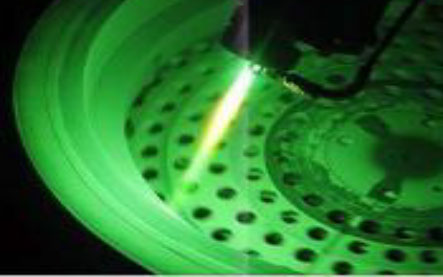

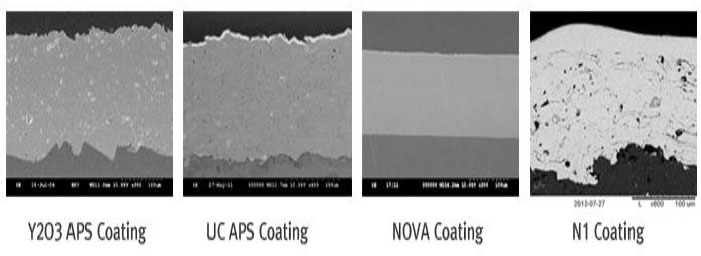

Plasma Spray Coating (Y2O3, Al2O3)

Special Material Coating (UC/BONO/SH/Silicon)

- Reduced Porosity and micro crack inside the coating layer for better plasma & chemical resistance

- Higher Surface Roughness (Ra) compared to Y2O3 coating layer

- Hold up more particle

- Minimize gas residue trapped inside the pore in coating layer

New Tech. & NANO Structure Coating (N1, NOVA)

- Less than 1% Porosity à High Density Coating

- Reduced Porosity and micro crack inside the coating layer

- Particle and Defect Control from part surface

- Excellent Plasma Resistance à Surface Corrosion & Erosion Protection

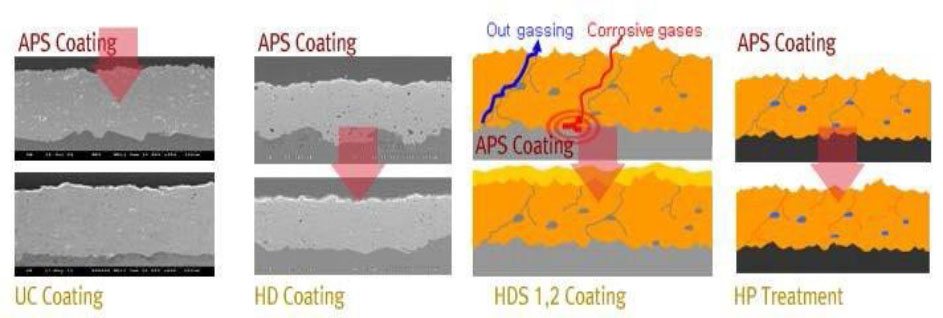

Various Types of Coating

| UC Coating | HD Coating | HDS 1,2 Coating | HP Treatment |

|---|---|---|---|

Features & benefits: This coating has high hardness and density, compared to Y203 by reducing internal defects (loser porosity and micro crack)

* Improved chemical and plasma resistance | Features & benefits: Minimized condition change inside the chamber by making a coating layer that can material quality of Y203

* Reduced particle from raw material & plasma damage and out gassing | Features & benefits: Coating which has big improvement on plasma resistance and surface stabilization by laminating high density coating on APS coating layer

* Stabilized Particle Trend in chamber with improving plasma resistance | Features & benefits: Shielded pore and connected channel with outside by sealing open pore and micro crack inside coating layer

* Reduced out gassing with covering micro channel |